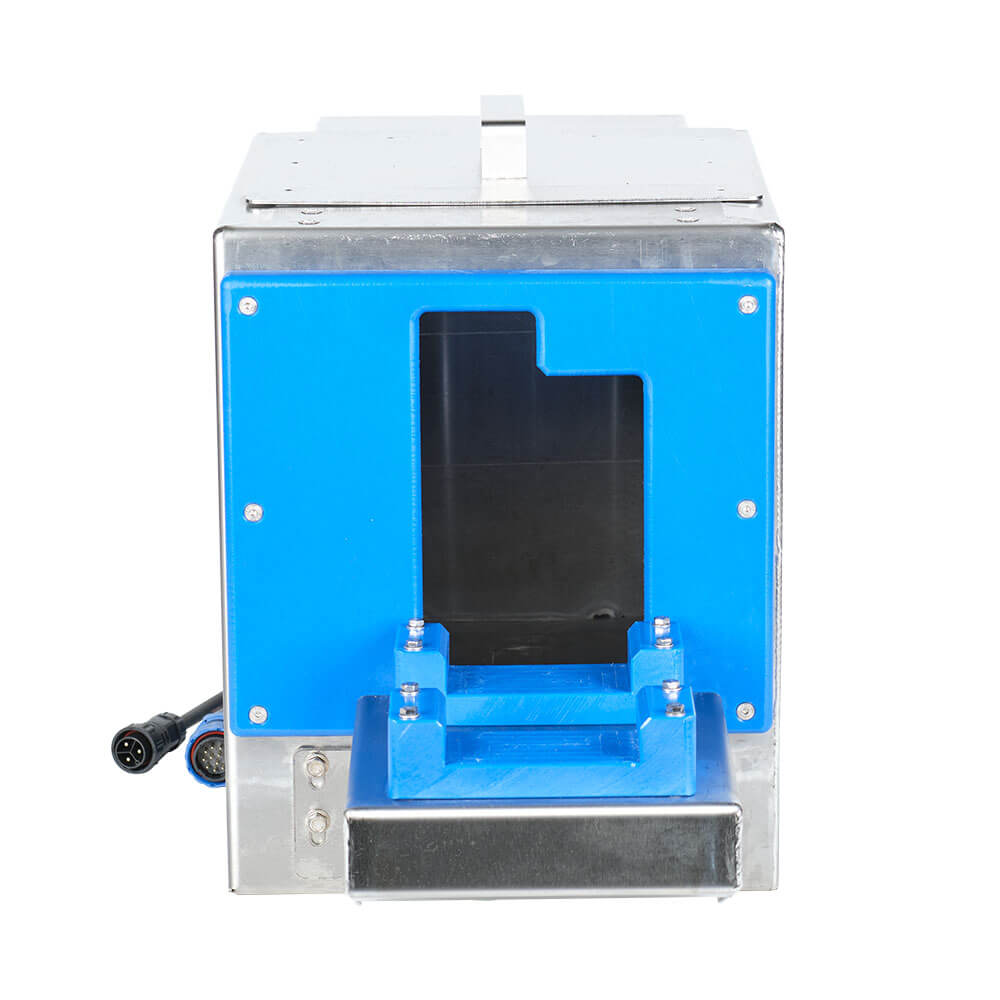

Circular Saw Steriliser Econoliser

Crafted to surpass traditional constant flow or water bath sterilisers, our solution emphasizes minimal water usage while ensuring superior tool sterilization.

Key Features:

- Achieves a remarkable 95% reduction in water consumption compared to constant flow immersion sterilisers, resulting in substantial cost savings.

- Guarantees at least a 95% reduction in water heating costs.

- Virtually eliminates steam production, reducing the risk of airborne contaminants condensing on surfaces and contaminating carcasses.

- Activates upon insertion of the tool into the unit, prioritizing operator safety and ease of use.

- Offers fully automatic operation, delivering consistent results with any operator.

- Incorporates a new easy access design for simplified servicing, minimizing downtime.

- Standard water level sensing feature automatically purges any air in the tank, preventing overheating of the heater element and thermal overload tripping.

- Compatible with all Econoliser models and water temperatures, optimizing efficiency regardless of water temperature.

- Built-in water heater ensures water temperature remains above 82°C, regardless of the water supply temperature (setpoint at 90°C).

- Enables the use of renewable energy sources due to minimal water and electrical energy consumption.

Optional Add-ons:

- External temperature display provides real-time monitoring of water temperature leaving the nozzles.

- Mounting column for convenient installation options.

Specifications:

- Voltage: 230/240V AC 50/60Hz;

- Max Load Current: 11A (water heater version);

- Minimum Dynamic Water Pressure: 3Bar;

- Minimum Sterilisation Water Flow Rate: 4.2L/min;

- Factory Set Sterilisation Cycle Time: 4.5secs;

- Water Used per Sterilisation Cycle: 0.280L ;

- Temperature Setpoint: 90°C.