Description

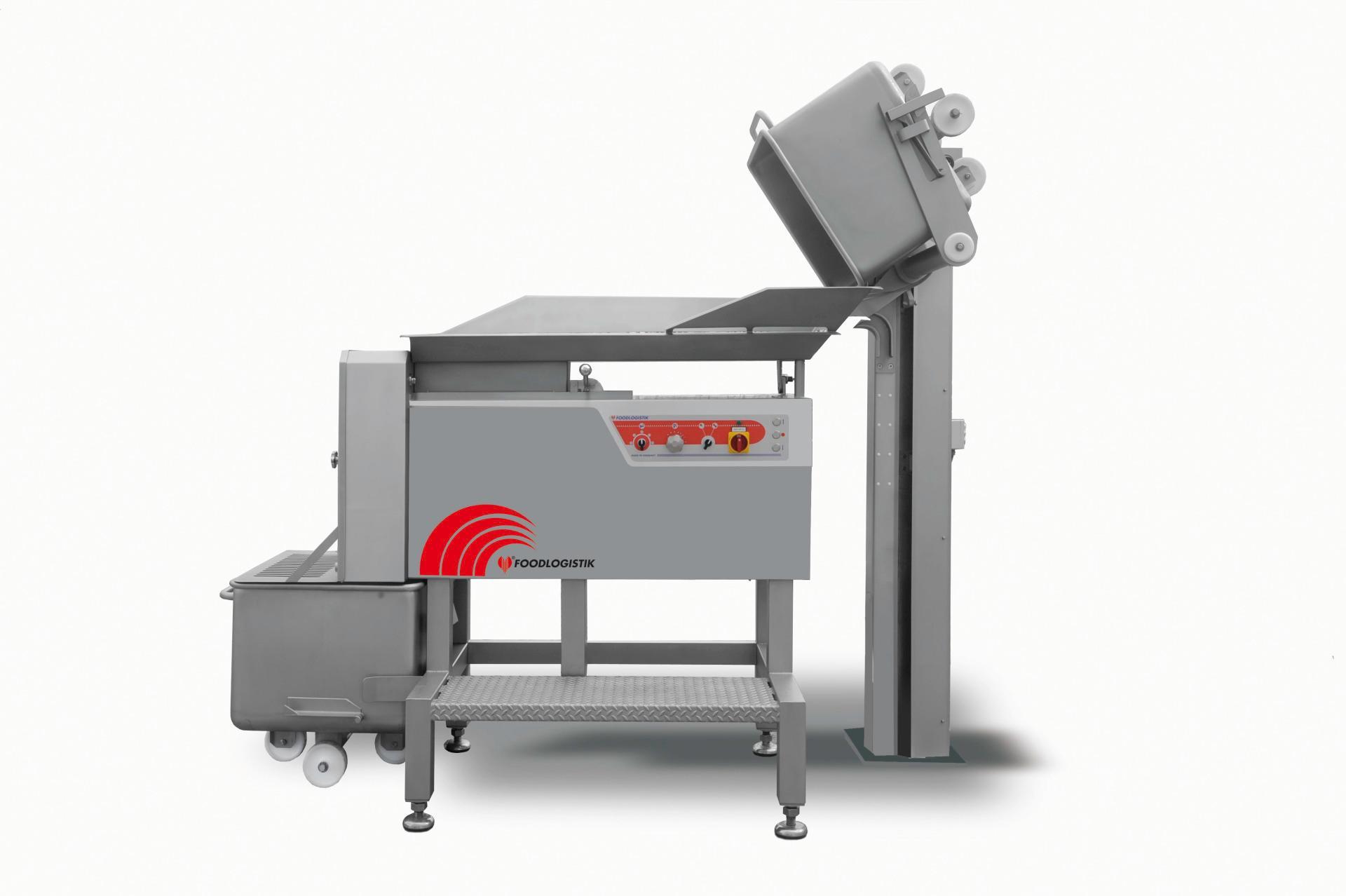

Product features: The large chamber size reduces product processing costs and increases processing capacity.

The loading chamber with a volume of 10.3 liters of the loading bin makes the recycling process larger and reduces the number and time of feeding.

To reduce manpower, the 200-liter lifting device (optional) is designed for large-volume production workshops.

Powerful hydraulic and grid drive systems ensure hygiene, integrated discharge conveyors, or feed cut products to the finished basket.

The electronic soft start reduces the mechanical load of the driving device and prolongs the service life of the wearing parts.

Vacuum pump displacement: 16 m 3/h

Working cycle: 15-30 seconds

Vacuum chamber size (length × width × height):350 × 370 × 150 mm

Overall dimensions (length × width × height):550 × 440 × 420 mm

Equipment net weight: 49 kg

Working voltage: 230V/50Hz

Equipment power: 0.55 kW

Sealing size/number: 350mm /1